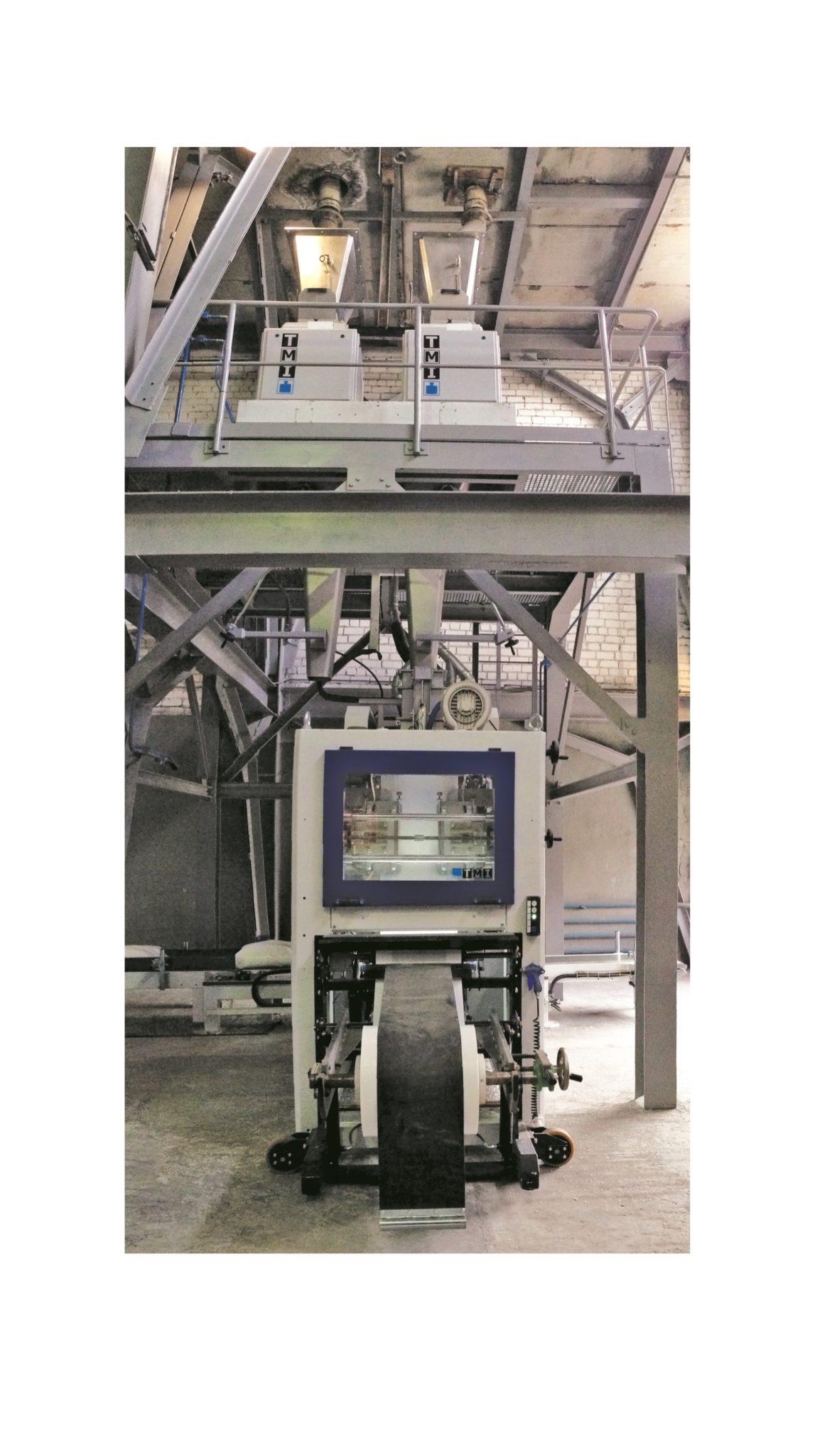

Ilerbag H Horizontal FFS Bagging Machine

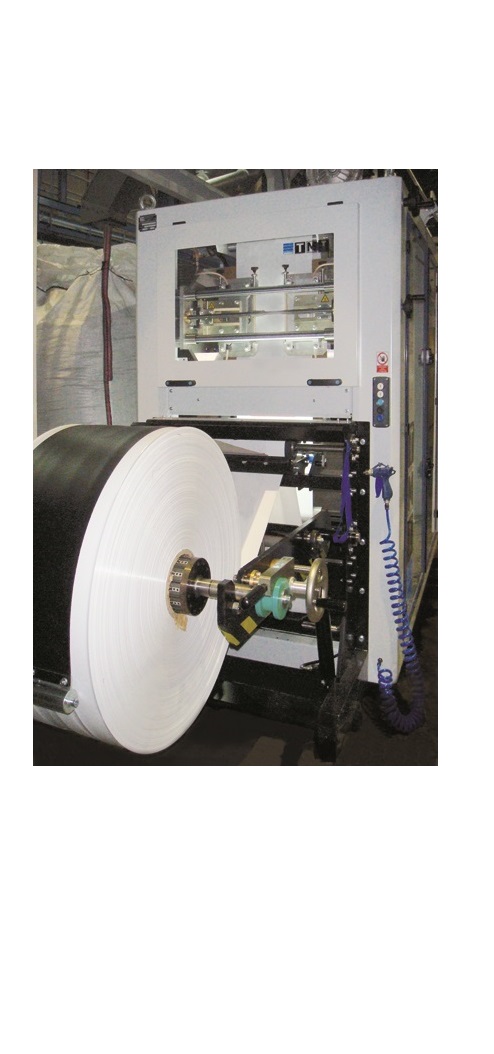

A fully automated bagging process from making, filling and sealing of the bags in one single bagging machine. The intelligent design of the FFS plastic bagging system uses long tubular reels that requires less replacement of consumables. The standardization of bag formats, by the use of the tubular reel, and the optimization of consumables translate into a significant reduction of the cost per bag.

Space maximization is a key feature of the Ilerbag H. It integrates the bag making, filling and sealing modules in a single unit. This makes it one of the most compact solutions on the market for automatic bagging in polyethylene bags and other heat-sealable compounds. Its design has considered maintenance, eliminating guides and barriers and providing this FFS bagging machine with utmost accessibility. It is also designed for fitting with modules that optimise the results, such as corner heat sealing, corner punching, air extraction from full bags, etc.

DOWNLOAD DATASHEET ROI CALCULATORCAPACITY:

1400 bags per/hour

BAG TYPE:

Form, fill, seal

Features

- Up to 1,400 bags per hour

- Total automation of the bagging process

- Quick return on investment

- Optimisation of consumables

- Optimised plant space

- Gentle, precise movements during the bagging process

- Easy maintenance

- Versatile configuration to achieve the results you need

- Forms gusseted corner seals

Options

- Reel entry at 90o to filled bag outfeed

- Thermal transfer printing built in

- Air extraction from inside the bag and/or injection of gas for modified atmosphere

- Seal cooling system with cooled air

- PE mesh conveyors for fine products

- Anti-corrosion versions for corrosive product

- ATEX versions for work in Hazadous Zones

- OEE modules and SCADA systems.

- Product collection systems under the bagging machine

- Mobile platform that moves on rails or wheels

- Hygienic version for food and pharma