Description

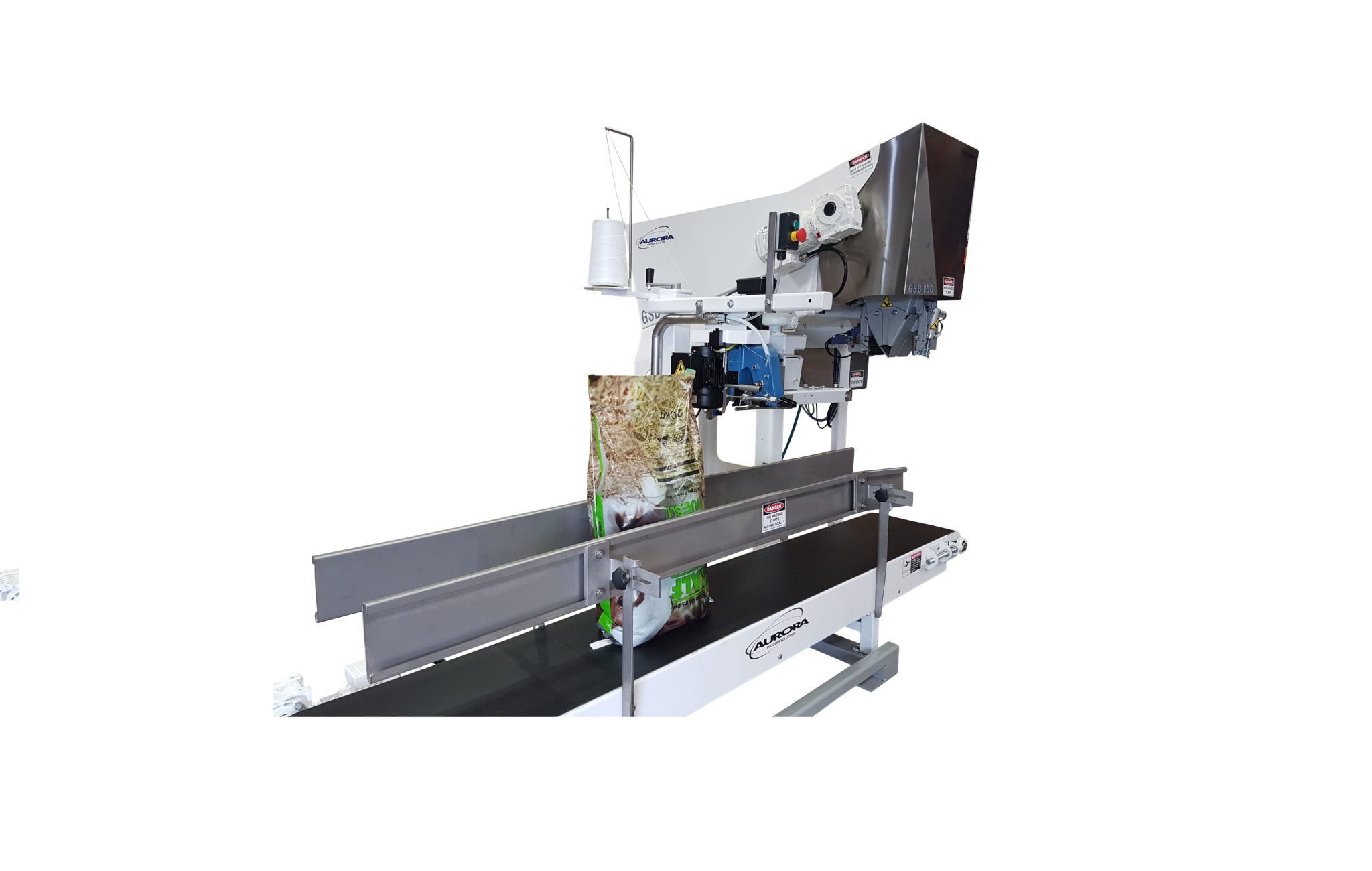

The Mini System is a Fischbein “FB” sewing head mounted on a pedestal for installation above a synchronized conveyor. A Fischbein Power in-feed unit together with various other options form an automatic sewing unit for general bag closing.